Kompatto 5030 Overview

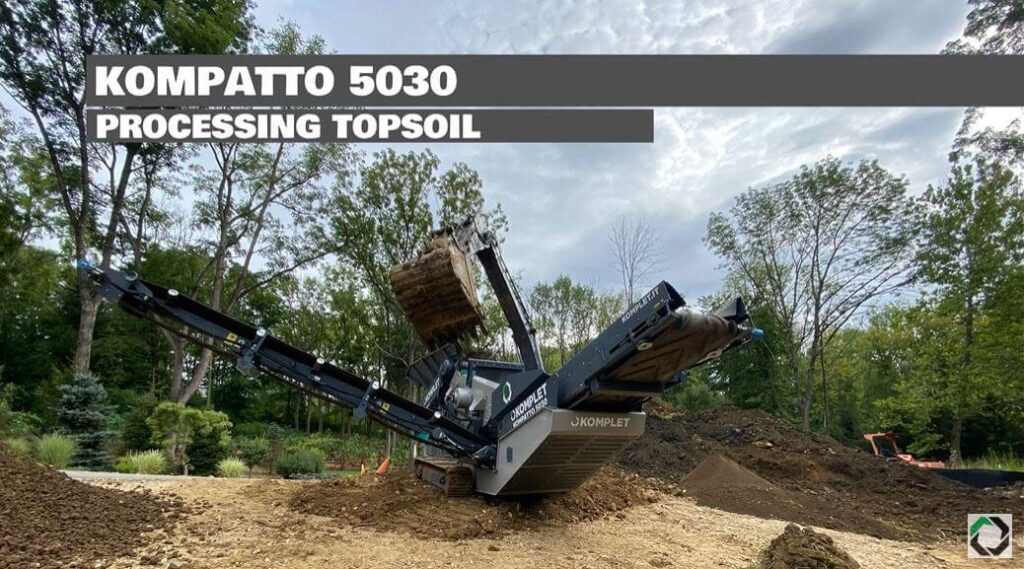

Kompatto 5030 is a vibrating screening machine that every construction worker should consider adding to his equipment. This compact scalping screen is the largest model of Komplet vibrating screeners. As with other Komplet crushing and screening equipment, they are self-propelled and specifically designed to enhance ease of transportation and versatility for operators.

The vibrating screen is compact enough to fit into a 40ft container for transportation. Yet, strong enough to carry out rugged applications and work in rough areas. Kompatto 5030 is compatible with steel mesh screens and features a wide range of screen media such as woven mesh, finger screens, punch plates, and bars. Thus, it’s applicable in several industries.

Kompatto 5030 Mobile Screener

Pros and Cons

Every Komplet equipment is known for its mobility, compact sizes, intuitive user interface, and high performance. The Kompatto 5030 is similar, featuring each of these and more.

Kompatto 5030 Mobile Screening Machine

Specification for Screener

| SPEC | |

|---|---|

| Warranty | 12 months / 1000 hours |

| Screen length | 2.5 meters |

| Screen width | 1 meter |

| Engine Horsepower | 45 hp |

| Screen Size | 8’10” ✕ 3’9″ |

| Drive power | 32 kilowatts |

| Maximum output | 280 US tons per hour |

| Type of screen | MS |

| Working Size (L ✕ W ✕ H) | 30’8″ ✕ 35′ ✕ 9’2″ |

| Transport Size (L ✕ W ✕ H) | 31’5″ ✕ 7’2″ ✕ 8’2″ |

| Weight | 12 tonnes |

Kompatto 5030 Mobile Screener

Screening Machine Features

- Remote-controlled.

- Variable feeder speed.

- Versatile screen box from scalping before and screening after the operation of crushing.

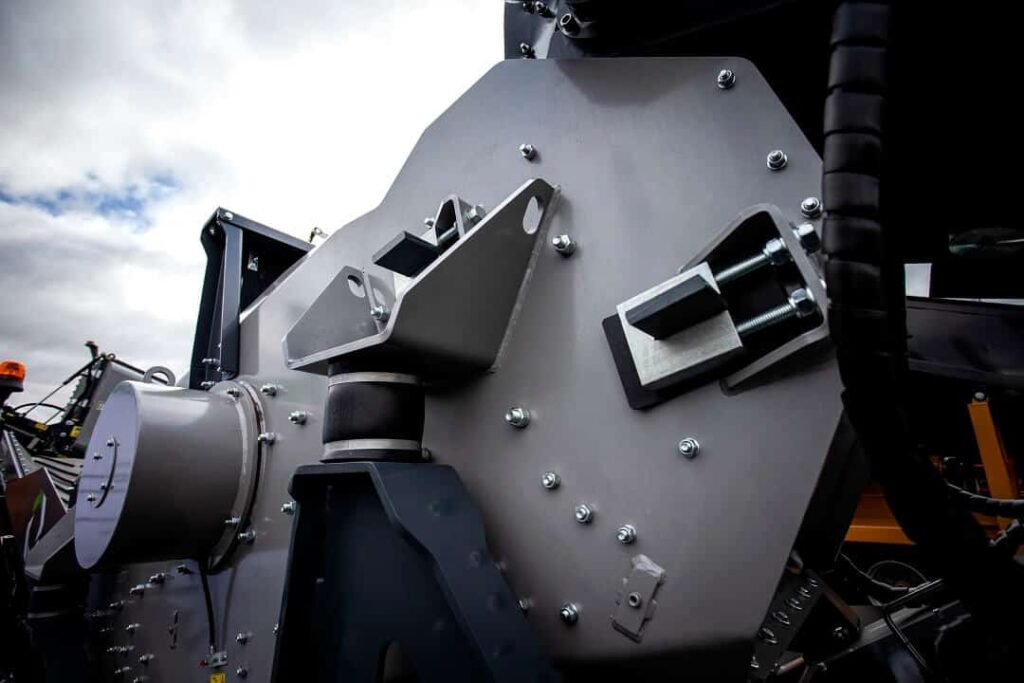

- Heavy duty single shaft incline screen box with adjustable stroke & speed.

- It’s quick to set up.

- Hydraulically folding conveyors.

- It can fit into a 40ft container.

- Fast conversion from 3-way split to 2-way split fully hydraulic for mixing oversize and midsize products optionally.

- Smart design minimized the weight of 12 tons.

- 12 months guarantee.

Kompatto 5030 Screener

Working Principle and Application

Similar to every vibratory screen, the main aim of the Kompatto 5030 is to screen materials into different size grades with vibration. As such, the working principle of the Komplet Kompatto 5030 involves the use of vibrations to break down the material and separate them into different sizes.

Typically, the fine particles pass through the screening surface while the oversized ones are left on the screen. Kompatto 5030 can accept any material up to 4 inches in width, but you should note that more oversized materials can damage the screen. The Komplet’s most prominent model of vibrating screener also features a configurable output belt for a quick conversation from 3 way split to 2 way split to meet your desired result.

A vibratory screen is one of the major types of industrial screening equipment. It is applicable in nearly all industrial industries for screening various materials such as aggregates, sand, gravel, construction demolition, debris, etc.

Compact Screener Kompatto 5030

User-friendly and Safe

Kompatto 5030 mobile crusher is user-friendly and safe equipment. The screener, equipped with tracks that are 9 inches long, 1.3 inches wide, and fitted with trackpads, can easily navigate around rough areas without jeopardizing the operator’s safety.

The large Komplet vibratory screener also features a user-friendly design that enables easy operation. One such feature is its intelligent remote control that you can use to aid the easy movement of the equipment.

Kompatto 5030 Mobile Screener

Compact Design and High Workload

Although the Kompatto 5030 is the largest Komplet screener, it has a compact design that aids its mobility and ease of transportation from site to site. The mobile screening plant’s 12,000kg / 26,455 lb weight can easily fit into a 40 ft container.

Additionally, 5030 has a high workload with a vibrating hopper with a maximum capacity of approximately 88.3 ft³. The Kompatto 5030 can produce about 250 to 280 US tph.

Add your rating

Summary

Kompatto 5030 is a piece of ideal equipment for every contractor because it can screen wet and dry materials and be used in pre-screening and final screening processes. It is also a fuel-efficient screener capable of a high workload and produces about 280 US tph.