Kompatto 221 Overview

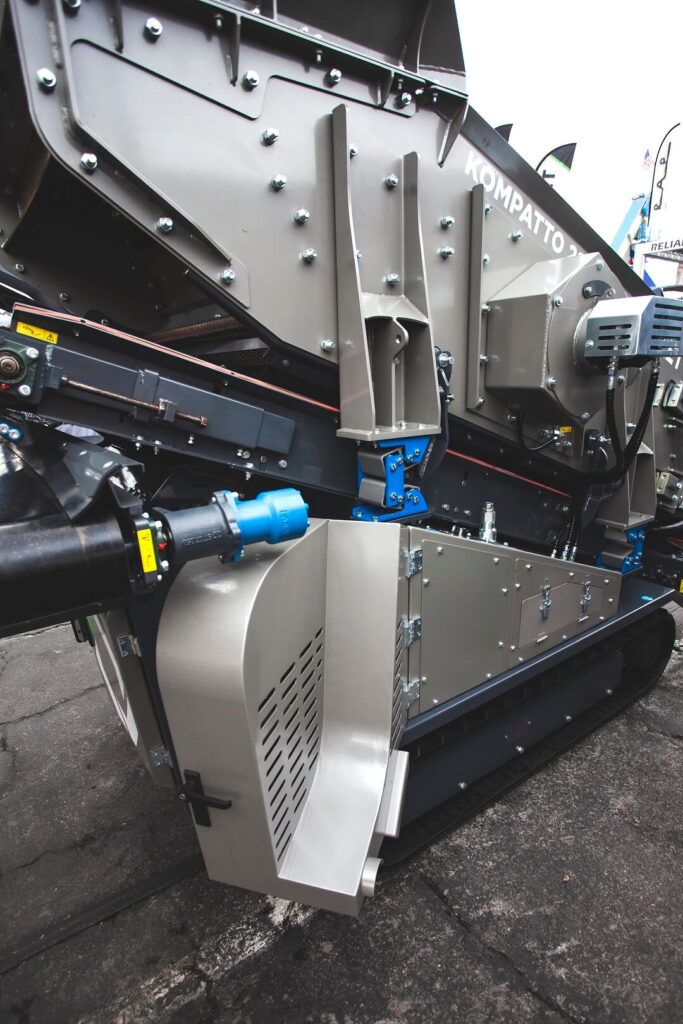

One of the smallest yet most powerful mobile screening machines produced recently is the Kompatto 221 mobile vibrating screener. It is designed to handle landscaping, recycling, excavating construction, and demolition sites. Its portable size and ease of carrying, including ease to set up, make the Kompatto 221 a good choice for these operations.

The machine runs on a 25 hp diesel engine with double screens on its vibrating system, each measuring 7′ x 35. This screener uses its small size as an advantage in entering places with limited access. They go as far as working up to 90 tons in an hour, going through the rubbles, and screening for useful materials in the waste. With Kompatto, you save money and time because you can directly recycle the crushed materials from the debris.

Kompatto 221 Mobile Screener

Pros and Cons

Kompatto 221 Screener Machine

Specification for Mobile Screener

| SPEC | |

|---|---|

| Warranty | 12 months / 1000 hours |

| Engine Type | Kubota Tier 4 Final |

| Engine Horsepower | 25 hp |

| Screen Size | 7′ ✕ 3.5′ |

| Production | up to 34 TPH |

| Working Size (L ✕ W ✕ H) | 12’8″ ✕ 10’7″ ✕ 8′ |

| Transport Size (L ✕ W ✕ H) | 12’8″ ✕ 7’3″ ✕ 7’3″ |

| Weight | 7,275 lbs |

Screener Kompatto 221

Features

- Double-deck screen box

- Small-sized for easy transportation

- Ability to process different-sized materials

- Wireless Remote control

Kompatto 221

Working Principle and Application of Screener

The first thing is to understand how a mobile screening machine works. Two components are built into the screening system: a drive and screen media. The drive generates the vibration while the screen media separates the different particle sizes. The double deck helps hold these two parts in place and serves as a means of transportation for the vibration.

For example, the Kompatto mobile screener has a double-deck screen recorder and a vibratory frame. In the screening process, the vibratory frame is fixed on springs, and the rotating wheel develops a volatile movement as soon as the vibration is generated. This screening filters the rubble and rubbish remaining in destroyed buildings and excavation sites.

Note that various factors can influence the whole process of screening, ranging from Gravitational force, electrostatic force, vibration rate, the material’s shape, and the bed’s thickness. And in some cases, there might be sticking and plugging due to water. And in some cases, if the materials are very dry, it can activate the release of a charge that can cause it to magnetize the screen surface.

Applications

As earlier said, the Kompatto mobile screener can be used to separate materials that are massed together in various sizes. The screener can also be used in construction, dewatering, dust and dirt removal, and washing.

Mobile screening is important in agriculture, construction, mining and mineral processing, recycling, and plastics.

Mobile Screener Kompatto 221

User-friendly and Safe

Kompotta mobile screener has an amazing user-friendly interface. They have been made very user-friendly, and they are compatible with other equipment used in construction, like tractors and excavators, because they are easy to use. Even though an equipment operator is put in place to ensure its proper functioning when screening is ongoing, it’s not always necessary and can be used occasionally.

Kompatto screening machines come with a manual guide that can be used to operate the machine and coupled with a simple interface. You can easily grasp the whole process. The machines can be arranged and set up on-site with ease to test to see that all parts are working as they should.

With Kompatto, everything is set accessible, and there is no safety you are putting at risk. It’s completely safe to use. Compared to other heavy mobile screeners, they are easy to transport. As far as trained experts operate the machines, Kompatto screeners can be moved from one place to the other on the construction site effortlessly and from one location to the other without any hassle or interfering with other ongoing operations.

And even with their size, they can be propelled on the site no matter the soil type, and even when they climb up mounds in construction sites, there is no difficulty in movement, contributing to having a safe working environment.

Kompatto 221

Compact Design and High Workload

It’s always easier to work with mobile screeners than the conventional static ones because of their functioning and compact design, which gives them an edge because they can be easily moved. The mobile machines function well in producing different sizes of construction materials.

Construction processes involving crushing, recycling, and sorting for useful materials from the rubble on construction sites are rigorous processes that only high-performance machines can handle. Because of the materials found in the rubble that need to be separated and processed, highly functional equipment that can handle that kind of intensive job is necessary.

Kompatto mobile screener is designed to do this kind of high-performance job and do it excellently. They perform different operations simultaneously, which makes work faster and easier and keeps the construction site more organized.

For instance, these mobile screeners do the crushing and sifting of materials simultaneously. They are made up of different mesh types that separate materials of different sizes. After which, it gathers them in well-set-up mounds. After the mesh separates them, they are transported to the conveyor belt to continue processing.

A disadvantage of low-performance screening machines is that it is limited to processing only a few materials due to their low capacity. But not with high-performance equipment like Kampottato, which is more efficient in handling materials with different degrees of toughness. They are very versatile and can handle just about any material that requires crushing and recycling on the construction site.

Mobile Screening Machine Kompatto 221 Details

Fringilla est ullamcorper eget nulla facilisi etiam dignissim. Augue ut lectus arcu bibendum at varius. Lectus magna fringilla urna porttitor. Ac turpis egestas sed tempus urna et pharetra. Libero nunc consequat interdum varius sit amet mattis vulputate.

Fringilla est ullamcorper eget nulla facilisi etiam dignissim. Augue ut lectus arcu bibendum at varius. Lectus magna fringilla urna porttitor. Ac turpis egestas sed tempus urna et pharetra. Libero nunc consequat interdum varius sit amet mattis vulputate.

Fringilla est ullamcorper eget nulla facilisi etiam dignissim. Augue ut lectus arcu bibendum at varius. Lectus magna fringilla urna porttitor. Ac turpis egestas sed tempus urna et pharetra. Libero nunc consequat interdum varius sit amet mattis vulputate.

Conclusion

Modern Innovations make work easier, and with the coming of mobile screeners, many people are choosing them over conventional static screeners. This is because these vibratory screeners have proven to be easy to use and efficient in separating materials, so what are you waiting for to purchase your Kompatto mobile screener? You can reach out to us today to get yours.