There are several different types of scalping screens available on the market today, each with its unique features and benefits. In this blog post, we will take a look at the six best scalping screens available and discuss their unique advantages. We will also provide tips on how to choose the right scalping screen for your needs and how to use it to make quick and accurate results. Whether you are a contractor looking to screen some construction materials, this blog is essential reading. Stay tuned!

Kompatto 5030 ScreenerKomplet – #1 of the Best Scalping Screens

Kompatto 5030 Mobile Screener BEST SELLER

Scalping screens are a type of sieve used to separate the smaller particles from the larger ones. They are commonly used in agriculture, construction and demolition, and other industries where fine materials must be removed without damaging the product.

Construction and demolition work particularly benefits from scalping screens because they can remove debris quickly and easily without causing damage or risking injuries. Scalping screens also help reduce dust accumulation, which helps avoid respiratory issues.

The basic principle behind all types of scalping screens is simple: They allow materials bigger than what can pass through the opening on one side (the sieve) while allowing smaller particles through on the other side (the discharge). This process helps reduce waste by removing only those items that need removal while leaving most materials in place. Scalping screens come in different sizes and configurations, so they can be custom-made for each job site.

To find the right scalping screen for your needs, it’s important to consider its specific features and price point. You also need to make sure that you understand how it works before making any purchase decisions.

The Kompatto 5030 Screener is one of the most versatile scalping screens available today. It can be used to screen sand, gravel, aggregates, C&D (construction & demolition), landfill material, topsoil, and other types of soil.

Here are some of its key features:

- The unique vibrating feeder technology ensures that all materials passing through the screener are vigorously shaken and disturbed. This leads to a more accurate measurement of both weight and size.

- The 48″ x 24″ sized screen provides ample room for various types of soils to be screened at once.

- The heavy-duty frame is built to last withstanding rugged conditions while providing accurate measurements time after time.

- The lightweight design makes it easy to transport and set up. It also folds down easily for storage when not in use.

- The screen is easy to use thanks to its intuitive controls and user-friendly interface. You can quickly scan large areas for any potential materials without manually moving the screener around.

Overall, the Kompatto 5030 Screener is an excellent choice for anyone looking for a reliable scalping screen that offers great performance. By using the Kompatto 5030 Screener, you can easily reduce the time and costs necessary to process different construction and demolition materials. Not only is the Kompatto 5030 Screener efficient and reliable, but it also comes with a range of features and specifications that make it a great choice for scalpers and mineral operators alike. If you’re interested in learning more about this amazing machine, be sure to visit our website and order it today. We offer hassle-free shipping and a wide range of payment options to make ordering easy and convenient.

Kompatto 221 Mobile ScreenerKomplet – #2 of the Best Scalping Screens

Kompatto 221 Mobile Screener BEST SELLER

At a construction and demolition site, the faster and more efficiently you can remove excess materials from the job site, the better. This is why scalping screens are so important – they allow you to quickly separate large or small material before it overloads your equipment.

Scalping screens come in different shapes and sizes, but they all have one common goal: to efficiently remove oversized materials from the workflow. By using a scalping screen correctly, you can avoid delays caused by overloading machines or having to waste time sorting through unusable material.

The Kompatto 221 Mobile Screener is among the most reliable vibrating screens available. It’s also one of the few mobile screener models that can handle a wide range of materials, including heavy ones like concrete. This makes it an ideal tool for contractors and others who need to quickly and easily separate large quantities of material.

Here are some key benefits of using the Kompatto 221 Mobile Screener:

- It’s fast and easy to use, making it ideal for small or medium-sized projects.

- The screen is extremely durable, able to handle even the heaviest materials with ease.

- It has a low noise level (making it perfect for noisy environments), as well as adjustable vibration intensity levels that make it comfortable to use.

- The Kompatto 221 Screen has been proven reliable, even under challenging conditions (such as heavy rain). Its vibration ensures that all materials are correctly separated.

- The Kompatto 221 Screen is small and lightweight, making it easy to transport and store. This makes it perfect for use in busy settings or areas with limited space.

So why is the Kompatto 221 Mobile Screener so popular? Its popularity stems from the fact that it is among the most accurate vibrating screens on the market today. Its ability to accurately separate various materials means that projects are completed faster and with fewer errors. Furthermore, its portable design allows users to carry it anywhere they go – making it perfect for use in construction sites or any other industrial environment where precise measurements are required.

If you’re in the market for a reliable vibrating screen that can handle a variety of materials, look no further than Kompatto 221 Mobile Screener. This equipment is made with high-quality materials and features a durable design that will withstand the test of time. Plus, it is available on our website at a price sure to meet your needs. If you’re interested in learning more about this product or ordering it, please don’t hesitate to get in touch. We would be happy to help you get the equipment you need to achieve successful results.

Barford SR124Barford – #3 of the Best Scalping Screens

When it comes to selecting the right scalping screen, there are a few important factors to consider. First and foremost, you need to decide which type of material you will be processing. Most screens can efficiently process soil, sand, gravel, coal, overburden, or demolition materials.

Second is the size of the screen. Some screens are designed for larger pieces of material, while others are specifically tailored for smaller items (like rocks). Finally, ensure that the screen has enough capacity to handle your workload – many screens come with features like bypasses and trapdoors that allow you to increase throughput easily. With these three factors in mind, finding the perfect scalping screen for your needs is easy.

If you’re in the market for a scalping screen, then Barford SR124 should be at the top of your list. This model is capable of processing most materials, including soil, gravel, coal, and demolition materials. It also has many other features that make it an ideal choice for any business. Here are some of its key benefits:

- Easy to operate and manage – The built-in controls make setup and use very easy. Plus, there’s no need to worry about maintenance because the scalping screen is durable and can handle heavy usage without breaking down.

- Versatile – The scalping screen can be used with a variety of materials. This makes it versatile enough for any business or project requirements.

- Excellent performance – The Barford SR124 is able to achieve high levels of productivity thanks to its superior design and construction quality.

- Long-lasting – Durable construction ensures a long life span and minimal downtime due to wear or tear.

- Customization – The mesh size is adjustable (to allow for customization), making this screen perfect for any application.

- Better performance – Its large opening allows it to take in more material than other models. This means you will get better results with less effort.

The Barford SR124 scalping screen is a high-quality, reliable scalping screen that can separate most construction and demolition materials. With its wide range of applications, this scalping screen is perfect for separating materials such as concrete, asphalt, bricks, and stones. Once you have had a chance to get acquainted with the Barford SR124 scalping screen, you’ll be able to see why it is one of the most popular options on the market.

By using the Barford SR124 scalping screen, you can maximize profits while reducing the time and effort required to collect material. If you’re looking for a reliable scalping screen that can handle a variety of materials, be sure to check out our website. We offer a wide range of models designed to meet your specific needs.

Ultra WAY SCREENERUltra – #4 of the Best Scalping Screens

Debris and other unneeded materials at construction sites can be a major safety hazard. By using a scalping screen, you can help to separate debris by size and avoid accidental injuries.

A scalping screen is a device that uses mesh or wire screens to capture small pieces of debris. The screens are mounted on an arm or conveyor belt, allowing them to move quickly across the work area. This helps you stay safe while you’re working and reduces the chances of injury from falling objects or sharp objects that may be hidden in debris piles up high.

Scalping screens are generally easy to operate, making them ideal for use at construction sites where time is precious. They also make it easier for you to clean up your area safely and quickly – no more missed deadlines.

The Ultra WAY SCREENER is a great option if you’re looking for an effective and efficient way to improve your landscaping. This machine can easily handle soil, compost, concrete, demolition waste, and topsoil. Plus, its many benefits are sure to please any landscaper or homeowner.

Here are some of the key reasons why this machine is such a hit:

- It’s easy to use – just load it up with whatever material you need to be cleared away and start pushing buttons. The advanced mechanism quickly separates all types of material pieces that flow through the screen easily.

- Its capacity is incredible – large amounts of debris can be handled in a single go without waiting long periods or struggling with heavy loads.

- It’s incredibly efficient – thanks to its unique design and hydroforming action, 99% of all debris is eliminated from the ground as it flows through the screen. This means less mess overall (and less work for your hired help!).

- It’s efficient – with its large size, the WAY SCREENER can quickly cover large areas.

- It’s durable – made from high-quality materials, the WAY SCREENER will last for years without requiring regular maintenance.

- It’s affordable; compared to other similar machines on the market, Way Screener is cheaper and more reliable.

- It’s versatile – the Way Screener can be used for small or large projects.

Eventually, if you are looking for a great scaping screen that can handle a variety of materials, Ultra WAY SCREENER is a great option. It is professional-grade and can hold soil, compost, concrete, demolition waste, and topsoil. This screen is perfect for larger projects or uses in areas where the surrounding environment is difficult to manage. By operating Ultra WAY SCREENER, you can ensure that your landscape is maintained in top condition without having to spend unnecessary time and resources. Plus, its durable construction makes it a long-lasting choice that will be sure to meet your needs. For more information about other similar options available, be sure to visit our website.

Titan 600Powerscreen – #5 of the Best Scalping Screens

A scalping screen is a device used in the construction and demolition industries to help separate large pieces of inconveniently shaped materials by size. By applying a scalping screen, contractors can reduce the time it takes to complete their job and ensure that they are getting the best possible value for their money.

Scalping screens are beneficial in situations where you have to deal with difficult-to-separate materials like bones or lumber. Removing smaller chunks of material from larger pieces can speed up your workflow and get more products per hour on the job site.

So why is a scalping screen such an important tool? Well, for one thing, it saves time on the job site – which means less waiting around for team members and more progress toward your project goals! And when it comes down to it – isn’t that what matters most?

The Titan 600 scalping screen is a versatile 2-deck screen specifically designed to separate construction and demolition materials. The Titan 600 is made from high-quality materials and construction, which makes it durable and able to handle heavy loads. It also has a modular design, which means that you can easily add or remove decks as needed. This makes the Titan 600 perfect for use in various settings, including construction sites, demolition zones, etc.

This revolutionary product has many features that make it unique and valuable, including:

- The screens are fast and easy to set up, making them ideal for quick turnarounds.

- The screens have adjustable sections that allow you to tailor the flow path width according to your needs. This makes it easier to separate large quantities of material quickly and accurately.

- The screens are made from high-quality materials that are durable and resistant to wear and tear. They will last long periods without the need for regular maintenance or replacement.

- Hydraulic arm suspension allows for smooth movement across the screens – even on slopes or uneven terrain.

- Dual discharge ports allow you to dispense material simultaneously onto the decks from either side.

- Easy-to-use controls make operation simple and easy.

- This screen can handle a lot of material at once, which makes it perfect for separating construction and demolition materials.

- Its tight construction tolerances mean you won’t have to worry about throwing away unusable material.

- An easy-to-use operator’s console with touch controls that allow you to operate the machine smoothly and efficiently.

Scalping screens are important tools that allow for the efficient separation of construction and demolition materials. By having a scalping screen, you can quickly and easily remove small pieces of debris from large piles of material. This is an essential tool for anyone working in the construction or demolition industry, and the Titan 600 is one of the best scalping screens on the market.

If you’re interested in learning more about similar screens or other models we offer, visit our website. We have detailed information about each screen, as well as model comparisons and reviews. This information will help you make an informed decision about which scalping screen is right for your needs.

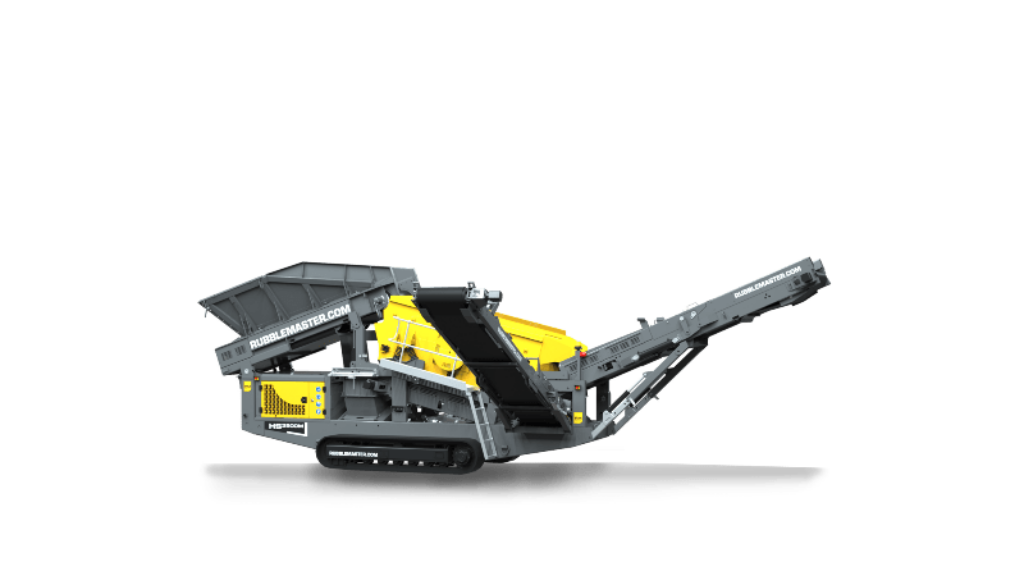

RM HS3500MRUBBLE MASTER– #6 of the Best Scalping Screens

Choosing a suitable scalping screener for separating construction and demolition materials by size can be confusing. There are many models on the market, each with unique features and benefits. It’s important to choose one that will suit your needs specifically to get the most accurate results possible.

There are a number of factors to consider when choosing an industrial scalping screener for separating construction and demolition materials by size. Factors that may be important include the type of material being screened, the accuracy and speed of the screener, and the ease of use.

Some types of material that may be screened using an industrial scalping screener include brick, concrete, asphalt, crushed stone, lumber, steel rafters/joists, etc. An industrial scalping screener should be able to accurately separate these items by size so that only appropriate amounts are delivered to the plant or site. This will help minimize wasted material and lower costs associated with incorrect deliveries.

Speed is also critical in this scenario – scalpers must be able to quickly process large volumes of material in order not to lose money on each load delivered. Finally, ease of use is key since many customers prefer machines they can operate without having extensive knowledge about construction material screening equipment.

All of these factors will determine how easy it is to accurately identify which material belongs in which pile or bin. Ultimately, making this decision effectively becomes a matter of speed and accuracy – two essential qualities when processing large volumes of material quickly and efficiently.

We have a great suggestion if you are in the market for excellent screening equipment. The RM HS3500M mobile scalping screen is a high-performance screening machine that can separate various materials, including topsoil, aggregates, sand & gravel, mulch, asphalt millings, excavated C&D waste, and more. Its highly aggressive screen can quickly and easily remove material from the site for further processing or disposal.

The RM HS3500M has many benefits that make it an attractive option for businesses in various industries. One of the main advantages of using this scalping screen is its aggressive nature. It can effectively chew through large volumes of material rapidly, allowing you to collect more resources in less time. The rugged construction makes it resistant to damage, ensuring that your equipment remains operational during hard working conditions.

This machine is simple to operate – just set your material size and start separating! You won’t have to worry about settings or adjustments; it automatically adjusts according to your needs. And its lightweight design means you can move it around quickly without having trouble lifting it.

Its speed and aggression are also perfect for separating various materials on the site. Besides, its large capacity allows it to handle large volumes of material at once. And finally, its sturdy construction makes it resistant to wear and tear.

The RM HS3500M mobile scalping screen is a highly aggressive screen that can separate a wide variety of applications and materials such as aggregates, sand & gravel, and more. The screen is designed for use in a mobile environment and can be quickly moved to different locations to maximize scalping opportunities. With its aggressive scalping capabilities, the RM HS3500M mobile scalping screen is perfect for separating various materials at various scales. If you are searching for a high-performance scalping screen that can handle a variety of materials and applications, the RM HS3500M mobile scalping screen is the perfect option.