Trommels, often referred to as trommel screens or trommel machines, are cylindrical drum-like devices used in various industries for sorting, classifying, and separating materials. These versatile machines have been instrumental in the fields of mining, waste management, composting, and construction, among others. In this article, we will delve into the definition, working principles, types, applications, advantages, and limitations and provide a selection guide for trommels.

Definition and Origin

The term “trommel” originates from the German word “trommel,” which means drum. Trommels have been used for centuries, with their history dating back to ancient times when they were initially developed as musical instruments and later adapted for various industrial applications.

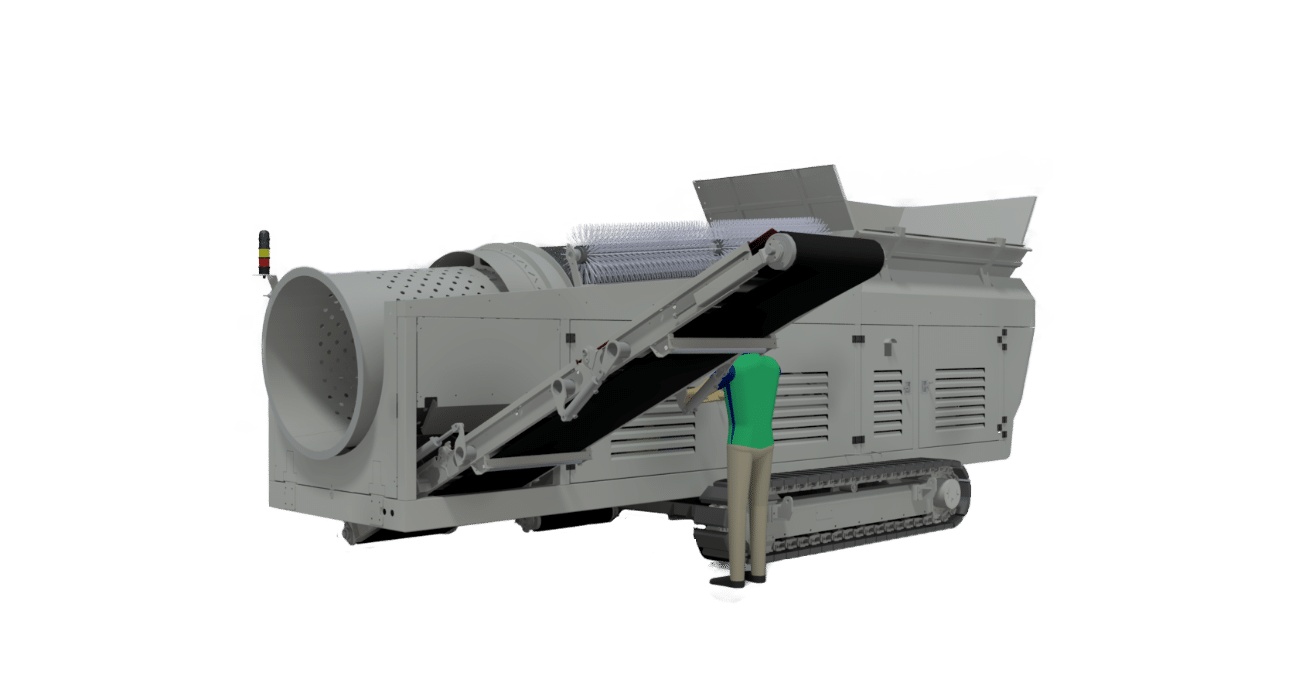

A trommel typically consists of a cylindrical drum made of various materials, such as metal, plastic, or rubber. Depending on the specific application, the drum is usually mounted on an inclined frame or placed horizontally. Inside the drum are perforated or woven screens of varying sizes, allowing materials to pass through while retaining larger objects.

How Trommels Work

Trommels operate on a simple yet effective principle of tumbling and screening. Here’s a basic overview of how they work:

- Material Loading: Raw material is fed into the trommel, usually at one end of the drum. This material can range from soil and rocks to waste debris or compost.

- Rotation: The trommel machine starts to rotate, causing the material inside the drum to tumble and move forward. The rotation is typically powered by an electric motor or an internal combustion engine.

- Screening: As the material tumbles inside the drum, smaller particles and fines fall through the perforated or woven screens, while larger objects like rocks and debris continue moving along the trommel’s length.

- Collection and Discharge: The separated materials are collected at the opposite end of the trommel from where they were initially loaded. These materials can then be further processed or transported as needed.

The effectiveness of a rock trommel in separating materials depends on factors such as the size and shape of the screens, drum rotation speed, and the angle of inclination.

Types of Trommels

Trommels come in various types, each designed for specific applications. The two primary categories of trommels are rotary trommels and vibrating trommels.

Rotary Trommels

Rotary trommels are the most common type and are widely used in industries like mining, quarrying, and waste management. They consist of a cylindrical drum that rotates around its axis. The rotation agitates and separates the materials inside the drum, allowing for efficient screening and sorting.

Vibrating Trommels

Vibrating trommels incorporate a vibrating mechanism within the drum in addition to the rotational movement. This added vibration helps to further separate materials by loosening particles and preventing clogging of the screens. Vibrating trommels are often used in applications where finer screening is required.

Trommel Screen vs. Drum Screen

It’s essential to distinguish between trommel screens and drum screens, as the terms are sometimes used interchangeably but refer to different equipment:

- Trommel Screen: A trommel screen includes the drum and the screens within it. It is designed for sorting and classifying materials based on size.

- Drum Screen: A drum screen is a simple rotating drum without screens, primarily used for removing debris and oversize particles from materials. It lacks the classification capabilities of a trommel screen.

Applications Across Industries

Trommels find applications in a wide range of industries due to their versatility and efficiency in material processing and separation. Here are some key sectors where trommels are commonly used:

Mining and Quarrying

Trommels are employed in the mining and quarrying industry to screen and separate ores, minerals, and aggregates. They help classify materials by size, allowing for more efficient downstream processing and improving the quality of the final product. Rotary trommels are particularly useful in this context.

Waste Management

Trommels play a crucial role in waste management facilities by separating recyclable materials from mixed waste streams. These machines efficiently separate organic waste, plastics, paper, and other recyclables, reducing the amount of waste that ends up in landfills. Vibrating trommels are often used in waste sorting facilities.

Composting

Composting facilities use trommels to sift and aerate composting materials. By removing contaminants and large particles, trommels help create high-quality compost that can be used as a soil conditioner or fertilizer. The screened materials are then ready for bagging or distribution.

Construction and Demolition

Trommels are used to sort and separate construction debris and demolition waste in construction and demolition operations. This helps recover valuable materials for recycling, such as concrete, bricks, and wood, while also reducing the amount of waste sent to landfills.

Advantages and Limitations

Trommels offer several advantages in material processing and separation, but they also have limitations and considerations that need to be taken into account.

Advantages of Trommels

- Efficient Screening: Trommels efficiently separate materials based on size, making them invaluable in industries where size classification is crucial.

- Versatility: They can handle a wide range of materials, from fine particles to bulky objects, making them suitable for various applications.

- Reduced Manual Labor: Trommels automate the process of sorting and classifying materials, reducing the need for manual labor and increasing productivity.

- Improved Material Quality: Trommels help produce higher-quality materials for further processing by removing contaminants and oversized particles.

- Environmental Benefits: Trommels contribute to waste reduction and recycling efforts, promoting sustainability and reducing the environmental impact.

Limitations and Considerations

- Maintenance: Trommels require regular maintenance to ensure they operate efficiently. Screens can become clogged or damaged, and bearings may wear out over time.

- Initial Cost: Acquiring and installing a trommel machine can be expensive, which may deter smaller businesses from investing in them.

- Noise and Dust: Some trommel machines can be noisy during operation, and dust may be generated, requiring appropriate mitigation measures.

- Screen Selection: Choosing the right screen size and type is critical to achieving the desired results. The wrong screen can lead to inefficiencies and reduced performance.

Trommel Selection Guide

Selecting the right rock trommel for your specific application involves considering several factors and following maintenance tips to ensure optimal performance.

Factors to Consider

- Material Type: Determine the type and characteristics of the material you need to process. Different materials may require specific trommel designs and screen configurations.

- Required Output: Define the desired output size or particle size distribution. This will guide you in selecting the appropriate screen size and type.

- Throughput Capacity: Consider the volume of material that must be processed per hour or day. Ensure that the chosen trommel can handle the required throughput.

- Space and Installation: Evaluate the available space for installing the trommel and any site-specific requirements.

- Maintenance and Durability: Choose a trommel with easily replaceable screens and accessible maintenance points to minimize downtime.

- Environmental Regulations: Be aware of any environmental regulations or noise restrictions that may apply to your location and select a trommel that complies with them.

Maintenance Tips

To keep your trommel in optimal condition, follow these maintenance tips:

- Regular Inspection: Perform routine inspections to check for wear and tear, screen damage, and mechanical issues.

- Screen Cleaning: Regularly clean the screens to prevent clogging and ensure efficient screening.

- Lubrication: Keep bearings and moving parts well-lubricated to extend their lifespan and reduce friction.

- Replace Worn Parts: Promptly replace worn screens, bearings, and other components to prevent breakdowns.

- Training: Train operators on proper trommel operation and maintenance procedures to maximize efficiency and safety.

Bottom Line

In conclusion, rotary or vibrating trommels are indispensable machines in various industries, offering efficient material separation and classification. Understanding their working principles, advantages, and limitations and considering the factors outlined in the selection guide can help businesses make informed decisions when investing in trommel machines. When properly maintained and used, trommels improve material quality, reduce waste, and enhance overall efficiency in industrial processes.