In the world of construction and demolition, crushing equipment plays a vital role. Among various crushing machines, jaw crushers stand out as a versatile solution. Two main types dominate this category: single toggle jaw crushers and double toggle jaw crushers. Understanding the differences between these two machines is essential for mining, quarrying, and recycling professionals.

Single Toggle Jaw Crushers

Definition and Operation

A single toggle jaw crusher is a type of crushing machine that uses compressive force to break down materials. It operates with a single toggle or point of leverage that moves a stationary jaw plate toward a fixed jaw plate. The crushed material is then discharged from the crusher at the bottom.

The single toggle jaw crusher working principle relies on the swing jaw, driven by an eccentric shaft. This swing jaw generates a downward and forward motion, which transfers to the crushing zone.

Advantages and Applications

One of the primary advantages of a single toggle jaw crusher is its simplified design, making it relatively lightweight. This simplicity means fewer mechanical parts, leading to a decrease in potential failure points and reducing the overall maintenance needs.

The force distribution in single toggle jaw crushers is even. As a result, they can handle hard, abrasive rocks and materials with low moisture content. These crushers are commonly used in mining operations, aggregate production, and recycling applications due to their high reduction ratio and excellent particle size control.

Double Toggle Jaw Crushers

Definition and Operation

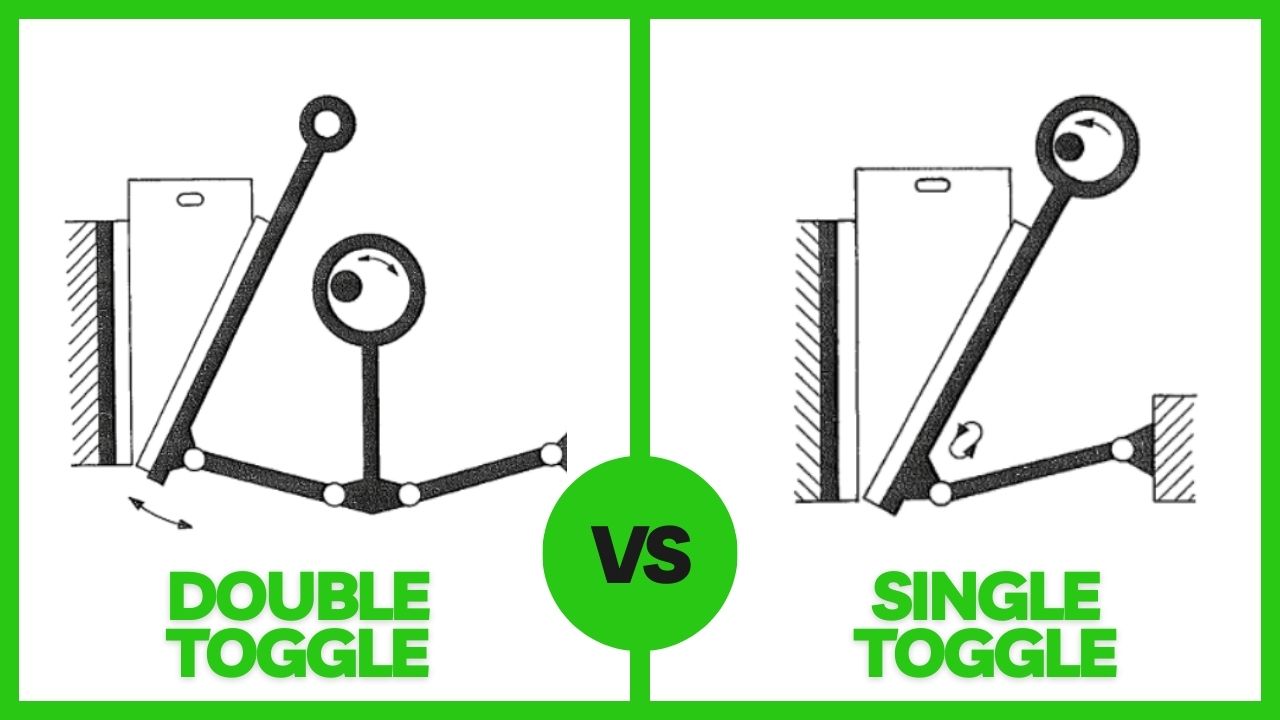

As the name suggests, double toggle jaw crushers utilize two toggle plates. Each of the two toggles is connected to the pitman, which, in turn, is connected to two swing jaws. When the pitman moves up, the swing jaws, acting like a nutcracker, crush the material that enters the crushing chamber.

The double toggle jaw crusher working principle involves a pitman that moves in a circular pattern, creating a unique crushing action with each cycle.

Advantages and Applications

One of the significant advantages of double toggle jaw crushers is their superior ability to handle high clay content or sticky material without substantial blockage. They also offer better control over the final particle size, producing a more uniform product.

Double toggle crushers are primarily used in heavy-duty applications such as hard rock mining and quarrying. These machines can handle larger feed sizes and high throughputs with high crushing force.

Key Differences

Structural and Design Variations

The structural and design differences between single and double toggle jaw crushers are noticeable. A single toggle crusher has a simpler, more compact design with fewer mechanical parts, whereas a double toggle crusher has a more complex structure with two toggle plates, a pitman, and two swinging jaws.

Mechanism and Motion Characteristics

The mechanism and motion characteristics of these crushers also differ. The single toggle jaw crusher produces a downward and forward motion, which results in higher throughput. On the other hand, the double toggle jaw crusher creates a nutcracker-like action with its unique circular motion, providing more control over the final product size.

Performance and Efficiency Comparison

Regarding performance, single toggle crushers have a higher throughput due to their straightforward crushing motion. However, double toggle crushers tend to have a more efficient crushing action, which results in less wear and tear on the machine, especially when dealing with abrasive materials.

Maintenance Tips and Best Practices

Proper maintenance is essential to keep any heavy-duty machinery running smoothly and efficiently, including single and double toggle jaw crushers. It extends equipment life, improves operational efficiency, and reduces the risk of downtime. Here are some essential maintenance tips and best practices for jaw crushers.

- Regular Inspections: Perform regular crusher inspections to catch issues early before they escalate. This includes checking the wear parts, belts, bearings, and tension of springs. Regular checks also help identify any material build-up which may lead to inefficiency or damage.

- Lubrication: Lubrication is crucial for the longevity and efficiency of the crushers. Ensure all moving parts are adequately lubricated per the manufacturer’s guidelines to prevent friction and wear. Check the oil levels regularly and change the oil at the recommended intervals.

- Cleaning: Regular cleaning prevents material build-up in the crushing chamber and other parts of the crusher. Over time, excess material can lead to blockages and affect crusher performance.

- Monitoring Crusher Performance: Keep track of the crusher’s performance by noting parameters like power draw, capacity, and reduction ratio. Any significant change could be a sign of an underlying issue that needs attention.

- Training: All personnel operating the crusher should be adequately trained in its operation and maintenance. This ensures the equipment is used optimally and safely, reducing the risk of accidental damage.

- Following Manufacturer’s Guidelines: Always adhere to the manufacturer’s operation, maintenance, and troubleshooting guidelines. This ensures optimal performance and safeguards the equipment’s warranty.

By following these best practices, operators can optimize the lifespan and efficiency of their jaw crushers, ensuring they deliver the best possible performance over time.

Factors to Consider

Choosing between a single or double toggle jaw crusher is contingent upon the specifics of the operation and the materials being processed. Here are several factors to consider:

- Feed Size: Double toggle crushers are more suited to processing larger feed sizes. Single toggle crushers might struggle with large boulders or highly consolidated material.

- Output Size: Double toggle crushers would be preferred if a uniform, smaller output is required. They offer better control over the final product size compared to their single toggle counterparts.

- Material Characteristics: The composition of the material significantly impacts the choice of crusher. Single toggle jaw crushers can handle hard, abrasive rocks more effectively, while double toggle jaw crushers work better with high clay content or sticky material.

- Throughput Requirements: Single toggle jaw crushers tend to have a higher throughput due to their straightforward crushing motion and thus might be preferable in situations where high productivity is required.

- Operational Costs: Single toggle crushers, due to their simpler design, have fewer parts and hence, lower maintenance costs. While offering certain operational advantages, double toggle crushers might incur higher maintenance costs due to their more complex mechanism.

- Site Conditions: Environmental and site conditions should also be considered. The size of the operation, the availability of maintenance resources, and the practicality of managing potential breakdowns can influence the choice between single and double toggle crushers.

In the end, the decision between a single toggle and a double toggle jaw crusher should be guided by the operational requirements and the specific conditions of each project. It’s advisable to consult with a professional who understands the intricacies of crushing technology to make an informed decision.

Summary

In conclusion, the single toggle and the double toggle jaw crusher have unique advantages and applications. A clear understanding of the difference between single and double toggle jaw crusher allows operators to choose the equipment that best suits their requirements, maximizing their productivity and efficiency.